Iran reaching technology to extract shale oil

TEHRAN – A pilot project for extracting shale oil in Iran is in its final steps and the country can be said to have access to the technology for extracting oil from such reserves, Shana reported.

The semi-industrial pilot project for shale oil production in Iran was designed to investigate the technical and economic aspects of the shale oil exploratory production process and to demonstrate the ability to exploit unconventional reservoirs on a laboratory scale, Shana reported.

The National Iranian Oil Company (NIOC) awarded the project to the Technical Faculties Campus of Tehran University in collaboration with Estonia’s Tallinn University in 2010 and now the project has reached its final steps.

Determining the thermal and geochemical characteristics and oil yield rate of oil shale reserves, determining the quality and physicochemical characteristics of oil extracted from shale reserves, providing the most efficient technology in order to achieve the maximum oil yield capacity of oil shale reserves, evaluating the oil yield capacity of Ghalikouh shale reserve in western Lorestan province, providing the most efficient mechanism and technology to obtain the highest quality shale oil, designing and building the first laboratory for exploratory shale oil production in Iran, as well as establishing and achieving the necessary technology for the implementation of the industrial phase of Ghalikouh shale oil reserve are said to be the main goals of the mentioned project.

Iran found shale oil reserves of two billion barrels of light crude in its western Lorestan province in February 2017.

“Based on studies, it is estimated that the shale oil reserves in Ghalikouh in Lorestan amount to two billion barrels of oil in place,” Bahman Soleimani, NIOC’s former deputy director for exploration, told Tasnim News Agency at the time.

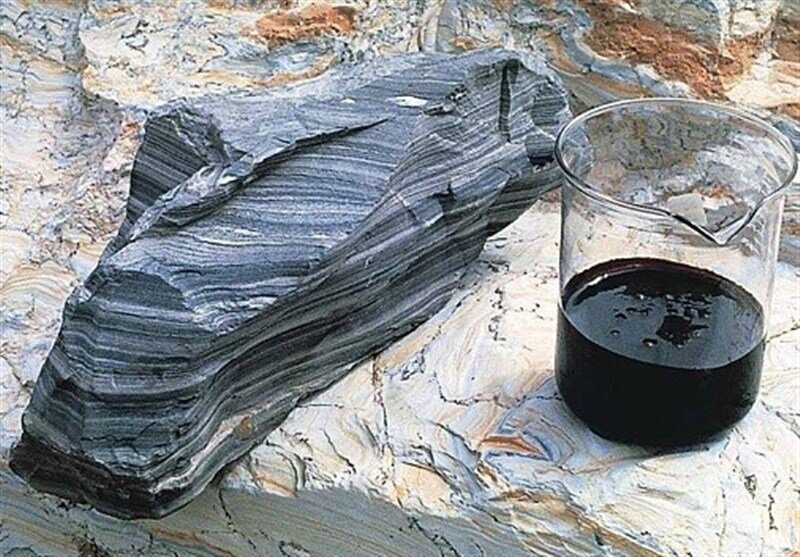

Shale oil is an unconventional oil produced from oil shale rock fragments by pyrolysis, hydrogenation, or thermal dissolution. These processes convert the organic matter within the rock (kerogen) into synthetic oil and gas. The resulting oil can be used immediately as a fuel or upgraded to meet refinery feedstock specifications by adding hydrogen and removing impurities such as sulfur and nitrogen. The refined products can be used for the same purposes as those derived from crude oil.

EF/MA

Leave a Comment